Overview

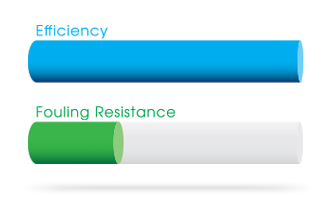

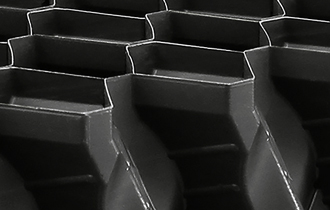

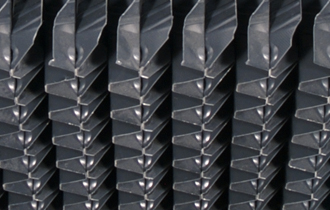

Cross-fluted designs provide high thermal performance and have alternating fill sheets, allowing for excellent lateral water dispersion. High thermal performance is achieved by utilizing the engineered microstructure design and maintaining the highest manufacturing standards.

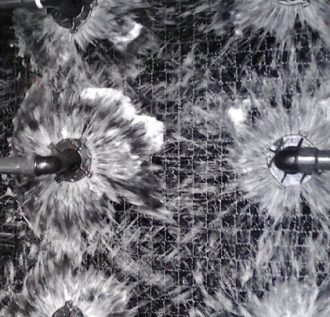

Brentwood has spent millions of dollars in R&D and testing of all cooling tower fill and drift eliminator products over the years, collecting results from thousands of high-performing installations. Whether your needs are for counterflow or crossflow tower applications, we can provide educated recommendations for the correct fill replacement to meet existing design criteria or improve upon older tower installations.

Cross-Fluted Fill Features

Available in material meeting Cooling Technology Institute (CTI) Standard 136

Available with AccuShield technology

Select products available with Mechanical Assembly technology

Learn More About Fill Products